Conveyor systems are an essential part of any kind of production line. They aid to relocate items around each phase efficiently as well as efficiently, lowering the chance of mistake that originates from manual labour. Selecting the best conveyor rollers for your system is vital to maintaining things running how you need them to, whether you’re aiming for quicker production times or lower expenses.

Conveyor Systems Utilising Gravity Rollers

Gravity Conveyor Rollers are typically the most effective priced on the marketplace, making them much more budget friendly for smaller companies. They can go for lower speeds than others on the marketplace and maintain your conveyors relocating with little effort, though they could produce rather a great deal of noise. Usually both hefty and light task gravity rollers are sold and a range of pins are offered, suggesting you can customise the product to your needs and conveyor system.

Conveyor Systems Using High-Speed Conveyor Rollers

High-speed conveyor rollers are frequently thought about a less affordable and advanced variation of gravity rollers. They are gained to minimise the amount of wear to the entire conveyor system and also to last a very long time themselves, and also they’re also very quiet to run. High-speed rollers can be utilised on a variety of conveyors including those that are chain and belt driven.

Grooved Rollers

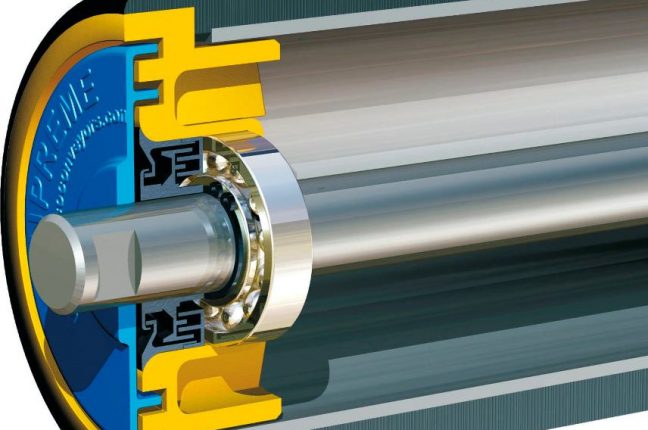

As the name recommends, these rollers have usually 1 or 2 grooves on their surface, though the variety of grooves could generally be customised to your needs. They are particularly for conveyor systems that are relocated only by rollers, and are extremely easy to install and also will certainly last a long period of time if utilised correctly. Grooved conveyor rollers are spring filled on either end and have kinky tube ends, aiding to protected bearings.

This web site www.conveyorrollers.co.uk offers quite a bit more info on the main topics rollers UK.

Should You Make Use Of Plastic Rollers?

Plastic conveyor rollers are usually quite cheap compared with metal options, and are best for lighter lots rather than sturdy. If your production is in a humid or wet environment after that these are the rollers for you. For ideal use, pair with stainless-steel bearings and spindles.

Utilising Stainless Steel Conveyor Rollers

Perhaps the most significant perk of stainless steel rollers is that, unlike various other metals, they’re corrosion resistant significance they’ll last longer and also are much more versatile. They can enter regular contact with water without rusting, and are likewise solid enough to handle heavy duty work. There are typically a wide range of tube class as well as spindles readily available in stainless steel.

Selecting Your Conveyor Roller

Now you have all the crucial details on these kinds of conveyor rollers, it’s time to make a decision which would certainly be best for you. There’s most likely currently been a couple that have stood out, say the gravity rollers for their inexpensive expense or the stainless-steel for being deterioration resistant, and also currently it’s time to whittle these to one. Take a look at your budget and be sensible about what you can pay for, then look at exactly what will be going on your conveyor systems and also which rollers will certainly be most fit to you. Once you have all the information, it’s not as well difficult to find the ideal rollers.

Categories

Business Review Websites

PSI Star Business Reviews, publishes business news on a weekly basis, other news websites that may be of interest to you include, www.aaronwilliamson.co.uk, www.beckysloan.co.uk, www.se-energy.co.uk and www.aslluk.co.uk – Quality business news every week!